Stop! Don't Replace Your Heat Exchanger—Restore It!

Is your existing unit experiencing reduced efficiency or breakdowns? Before you commit to a new purchase, Narmada Engineering offers a superior, cost-effective, and guaranteed restoration solution.

We specialize in bringing your existing units back to peak performance, ensuring they operate "as new" in all critical aspects of efficiency and reliability.

Our Proven End-to-End Restoration Procedure

We follow a meticulously planned, multi-stage procedure executed by certified experts to deliver guaranteed results with minimal downtime.

On-Site Assessment

Our team is deployed to your facility to conduct an in-depth inspection and use advanced diagnostics to pinpoint the root cause of failure.

Flexible Execution

We offer flexible solutions, including **In-Situ (On-Site)** repair to reduce costs, or **Ex-Situ (Workshop)** repair for complex fabrication work.

Precision Replacement

We procure or manufacture all replacement parts (tubes, baffles) to meet API/ASME standards, using state-of-the-art expansion tools.

QC & Guarantee

No unit is returned without passing rigorous QC checks, including hydrotesting and leak detection, ensuring it performs like new.

Final Quality Control (QC) & Performance Guarantee

| QC Inspection Aspect | Test Method | Purpose |

|---|---|---|

| Pressure Integrity | Hydrotesting (Tube & Shell) | Verifies structural integrity and confirms zero leakage under maximum design pressure. |

| Micro-Leak Detection | Helium Leak Test | Detects minute leaks often missed by standard pressure tests, critical for vacuum applications. |

| System Sealing | Pneumatic Test | Confirms the integrity of flange joints and final assembly seals before fluid introduction. |

Our Expert Field Services

We provide a comprehensive suite of on-site services dedicated to restoring, maintaining, and optimizing your shell and tube heat exchangers.

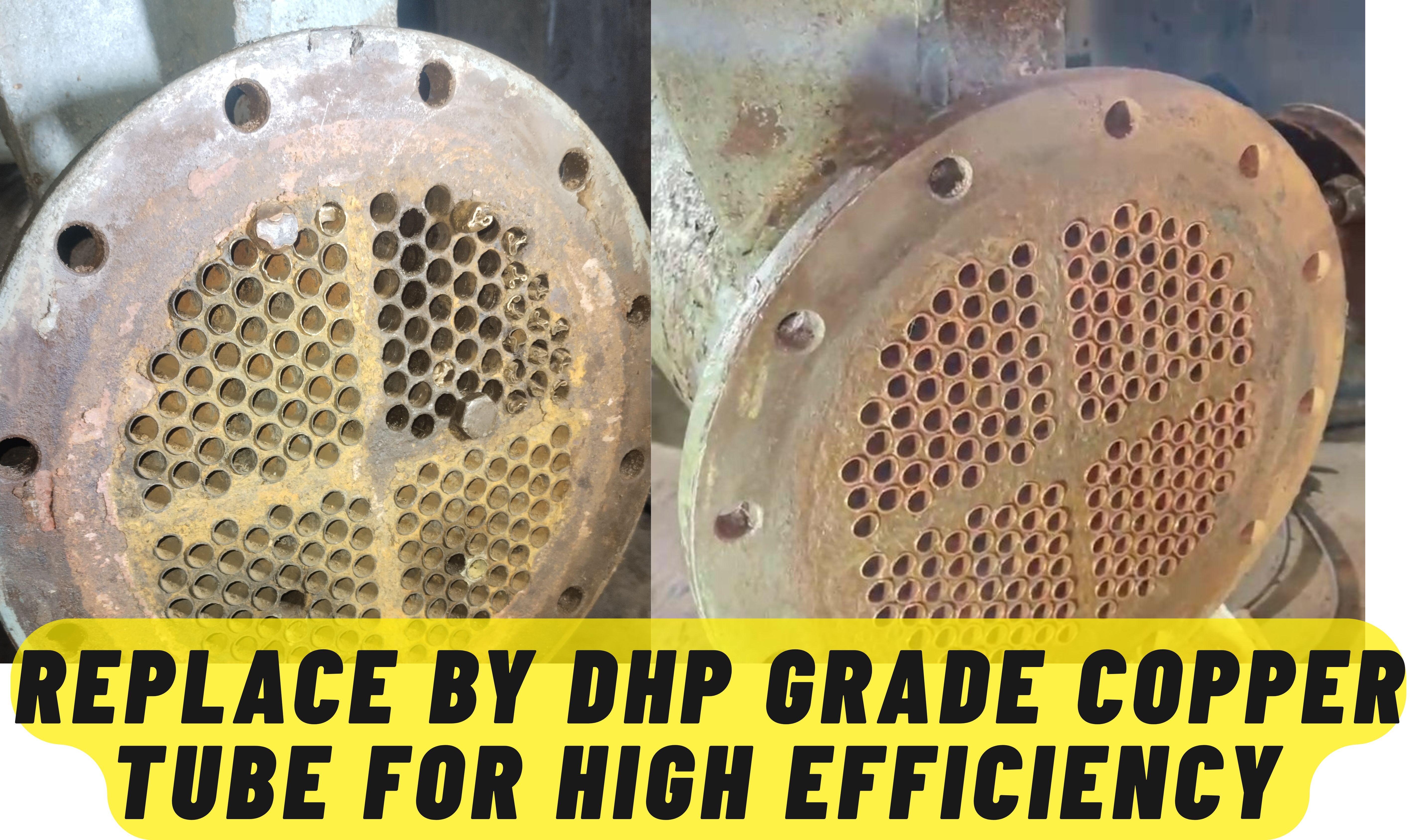

Precision Retubing

Our technical team has executed over 100 major on-site retubing projects. We bring unparalleled expertise to your facility, ensuring minimal downtime.

- Complete & Partial Tube Bundle Replacement

- Expert Tube Extraction & Insertion

- On-Site Tube Plugging & Repair

Equipment Expertise:

Power Plant Condensers, Process Coolers, HP & LP Heaters, Radiators, Evaporators & Chillers.

Advanced Testing & Inspection (NDT)

We use state-of-the-art diagnostic technology to accurately assess equipment condition, pinpoint failures, and ensure operational integrity.

- **Hydrotesting:** Pressure testing to verify structural integrity and leak tightness.

- **Helium Leak Detection:** High-sensitivity method for locating micro-leaks.

- **IRIS (Internal Rotary Inspection System):** Advanced ultrasonic technique for precise internal tube wall thickness data.

Industrial Cleaning Solutions

Our specialized services remove tough deposits and biological fouling, dramatically restoring thermal efficiency and flow.

- **High-Pressure Hydro-Jetting:** Removes hard scale, sludge, and blockages.

- **Chemical Cleaning (CIP):** Dissolves stubborn scale, rust, and process deposits.

Need Urgent Service?

Our rapid-response team is ready to help. Contact us for a consultation to diagnose your issue and recommend the right solution.

Get a Consultation